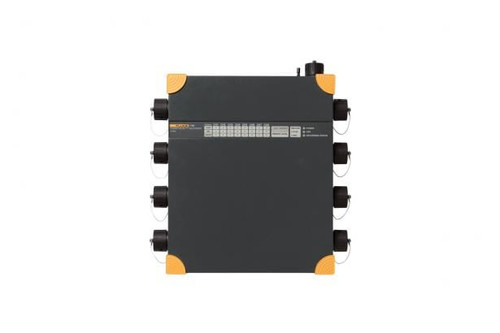

The Fluke 1742, 1746 and 1748 Three-Phase Power Quality Loggers give you fast, easy access to the data you need to make critical power quality and energy decisions in real-time. With the included Energy Analyze Plus software package you can easily create detailed reports.

Get the Fluke Guide to Choosing Power Quality Tools

Upgrade according to future needs

The Fluke 1748 logs over 500 different parameters for each averaging period. This allows you to analyze power quality in detail and to correlate intermittent events with detailed waveform data, helping to identify the root cause of disturbances. For basic power quality logging, the Fluke 1746 captures all relevant power parameters for performing energy saving studies and electrical network planning with a full upgrade option to 1748 available. For simple load and energy studies the Fluke 1742 offers optimal performance in a rugged package and can be upgraded to 1746, or complete 1748, functionality.

National and international standards

Compact and rugged, the Fluke 1740 Series Three-Phase Power Quality Loggers are designed specifically for technicians and engineers who need the flexibility to troubleshoot, quantify energy usage and analyze power distribution systems. Fully compliant with international power quality standards such as IEC 61000-4-30 Class A and capable of simultaneously logging up to 500 parameters while also capturing events, the Fluke 1740 Series helps uncover intermittent and hard-to-find power quality issues more easily than ever. Energy Analyze Plus software quickly assesses the quality of power at the service entrance, substation, or at the load, according to national and international standards including EN 50160 and IEEE 519.

An optimized user interface, flexible current probes, and an intelligent measurement verification function that allows you to digitally verify and correct connections makes setup easier than ever and reduces measurement uncertainty. Minimize your time in potentially hazardous environments and reduce the hassle of suiting up in PPE by using a wireless connection (Wi-Fi) to view data directly in the field.

Analysis and reporting

Capturing logged data is just one part of the task. Once you have the data, you need to create useful information and reports that can be easily shared and understood by your organization or customers. Fluke Energy Analyze Plus software makes that task as simple as possible. With powerful analysis tools and the ability to create customized reports in minutes youÕll be able to communicate your findings and quickly solve problems so you can optimize system reliability and savings. A range of built-in report templates for industry standards such as EN 50160, IEEE 519 and GOST enable one-click reporting so you can create high quality reports at the touch of a button. Reports can be modified as standards evolve, or new versions become available.

Which power logger is right for you?

| Features | 1742 | 1746 | 1748 |

| Functions | |||

| Voltage, current, power, power factor, frequency | ¥ | ¥ | ¥ |

| Energy forward/reverse | ¥ | ¥ | ¥ |

| Peak Demand | ¥ | ¥ | ¥ |

| THD | ¥ | ¥ | ¥ |

| Flicker | ¥ | ¥ | ¥ |

| Voltage and current harmonics (to 50th)1 | ¥ | ¥ | |

| Unbalance1 | ¥ | ¥ | |

| Rapid voltage change events1 | ¥ | ¥ | |

| Interharmonics (to 50th)1 | ¥ | ¥ | |

| Dips, swells, interruption and transient events tables1 | ¥ | ¥ | |

| Inrush current1 | ¥ | ¥ | |

| Transients (low frequency) / Waveform deviation events2 | ¥ | ||

| Recording | |||

| Trend | ¥ | ¥ | ¥ |

| Waveform snapshots2 | ¥ | ||

| RMS profile2 | ¥ | ||

| Communication | |||

| Ethernet | ¥ | ¥ | ¥ |

| USB (mini B) | ¥ | ¥ | ¥ |

| Wi-Fi download Instrument to device | ¥ | ¥ | ¥ |

| Wi-Fi download via Wi-Fi hub (free with registration) | Opt. | Opt. | Opt. |

| Included accessories | |||

| Flexible current probe | not /B version | not /B version | not /B version |

| USB stick | ¥ | ¥ | ¥ |

| USB cable | ¥ | ¥ | ¥ |

| 3PHVL-17XX cable assembly | ¥ | ¥ | ¥ |

| FLUKE-17XX-TL 0.18M test lead set | ¥ | ¥ | ¥ |

| FLUKE-17XX-TL 2M test lead set | ¥ | ¥ | ¥ |

| Alligator clips | 4 | 4 | 4 |

| 173x/174x Soft Case | ¥ | ¥ | ¥ |

| Cable marker kit | ¥ | ¥ | ¥ |

| MP1-3R/1B-Magnet Probe 1 set (3 red, 1 black) | Opt. | 1 | 1 |

| 174x-Hanger Kit | Opt. | Opt. | ¥ |

Software features

- "In-workshop" or "in-the-field" setup and download through PC application software: simple download using USB memory stick, Wi-Fi download, wired Ethernet connection or via USB cable.

- Energy Analyze Plus application software: Download and analyze every measured detail of energy consumption and power quality state-of-health with automated reporting.

- One-touch reporting: Create standardized reports according to commonly used standards like EN 50160, IEEE 519, GOST 33073 or export data in PQDIF or NeQual compatible format for use with third party software.

- Advanced analysis: Choose any available logged parameter to create a highly customized view of logged measurements for advanced correlation of data.

Hardware features

- Measure all three voltage and current phases plus the neutral current: Three-phase and neutral voltage leads and four flexible current probes or optional current clamps for CT secondary current.

- Comprehensive logging: More than 20 separate logging sessions can be stored in the instrument. A comprehensive range of power and power quality variables are automatically logged so you never lose measurement trends.

- Measure with premium accuracy: Meets the rigorous IEC 61000-4-30 Class A Edition 3 standard for ÔTesting and measurement techniquesÐPower quality measurement methods.'

- Capture dips, swells and interruptions: The 1748 includes event waveform capture and RMS event profile, along with date, timestamp and severity information to help pinpoint potential root causes of power quality issues.

- Measure key power quality parameters: Measures harmonics and interharmonics for voltage and current, also includes unbalance, flicker and rapid voltage changes.

- Optimized user interface: Capture the right data every time with quick, guided, graphical PC based application setup and reduce uncertainty about your connections with an intelligent verification feature and the only auto-correction function for a power quality logger. Connection errors are automatically indicated via an amber light on the unitÕs power button, this light turns green once corrected.

- Optimized user interface: Quick, guided, graphical setup ensures youÕre capturing the right data every time, and the intelligent verification function indicates correct connections have been made, reducing user uncertainty.

- Flexible power supply: Powers directly from the measured circuit with the widest available range for a power quality logger automatically going from 100 V to 500 V or from a wall line cord, so you can test anywhere.

- Rugged and reliable: Designed to withstand harsh installation environments with IP65 rating when used with IP65 voltage input adapter.

- Two external USB ports: One for PC connection and another for quick, simple data download to standard USB thumb drives, allowing you to leave the measurement device in place and download without disrupting logging.

- Ethernet connectivity: Wired and wireless connections for instrument setup and high-speed data download.

- Compact size: Designed to fit in tight spaces and panels with small 23 cm x 18 cm x 5.4 cm (9.1 in x 7.1 in x 2.1 in) footprint.

- Highest safety rating in the industry: 600 V CAT IV/1000 V CAT III rated for use at the service entrance and downstream.

- Optimized measurement accessories: Unique tangle-free flat voltage cable and thin flexible current probes ensure easy installation even in tight spaces.

- Battery life: Four-hour operating time (backup time) per charge on lithium-ion battery to withstand temporary power disruptions.

- Security: Safeguard your best asset from theft with a standard chain or other security device.

- Magnetic hanger kit: Conveniently stow the instrument safely inside or outside of electrical panels; compatible with all models and included with 1748 model as standard.

Key features

- Measure key power quality parameters harmonics and interharmonics for voltage and current, unbalance, flicker and rapid voltage changes.

- Measure with premium accuracy rigorous IEC 61000-4-30 Class A Edition 3 standard for ÔTesting and measurement techniquesÐPower quality measurement methods.'

- One-touch standardized reporting including EN 50160, IEEE 519, GOST 33073 or export data in PQDIF or NeQual compatible format for use with third party software using Fluke Energy Analyze Plus Software.

| Specifications | |||||

| Accuracy | |||||

| Parameter | Range | Maximum Resolution | Intrinsic Accuracy at Reference Conditions (% of Reading +% of Range) | ||

| Voltage | 1000 V | 0.1 V | ±0.1 % of nominal voltage 1, 2 | ||

| Current: Direct input | i17xx-flex 1500IP 24 1500 A | 150 A | 0.01 A (min. 1.5A)3 | ±(1% + 0.02%) | |

| 1500 A | 0.1 A | ||||

| i17xx-flex 3000IP 24 3000 A | 300 A | 0.01 A (min. 3.0 A)3 | ±(1% + 0.03%) | ||

| 3000 A | 0.1 A | ||||

| i17xx-flex 6000IP 36 6000 A | 600 A | 0.01 A (min. 6.0 A)3 | ±(1.5% + 0.03%) | ||

| 6000 A | 0.1 A | ||||

| i40s-EL clamp | 4 A | 1 mA | ±(0.7% + 0.02%) | ||

| 40 A | 10 mA | ||||

| Frequency | 42.5 Hz to 69 Hz | 0.01 Hz | ±(0.1%)2 | ||

| Auxiliary input | ±10 V dc | 0.1 mV | ±(0.2% + 0.02%) | ||

| Voltage min/max | 1000 V | 0.1 V | ±0.2 % of nominal input voltage1 | ||

| Current min/max | Defined by accessory | Defined by accessory | ±(5% + 0.2%) | ||

| THD on voltage | 1000% | 0.10% | ± 2.5% | ||

| THD on current | 1000% | 0.10% | ± 2.5% | ||

| Voltage harmonics 2nd to 50th | 1000 V | 0.1 V | ³ 1 V: ±5% of reading | ||

| < 1 V: ±0.05V | |||||

| Current harmonics 2nd to 50th | Defined by accessory | Defined by accessory | ³ 3% of current range: ±5% of reading | ||

| < 3% of current range: ±0.15% of range | |||||

| Flicker PLT, PST | 0 to 20 | 0.01 | 5% | ||

| Current probe accuracy | |||||

| Parameter | Influence quantity | iFlex1500IP-24 | iFlex3000IP-24 | iFlex6000IP-36 | i40S-EL |

| 150 A / 1500 A | 300 A / 3000 A | 600 A / 6000 A | 4 A / 40 A | ||

| Active Power P | PF ³ 0.99 | 1.2% + 0.005% | 1.2% + 0.0075% | 1.7% + 0.0075% | 1.2% + 0.005% |

| Active Energy Ea | |||||

| Apparent power S | 0 ² PF ² 1 | 1.2% + 0.005% | 1.2% + 0.0075% | 1.7% + 0.0075% | 1.2% + 0.005% |

| Apparent Energy Eap | |||||

| Reactive power Q | 0 ² PF ² 1 | 2.5% of measured apparent power | |||

| Reactive Energy Er | |||||

| Power Factor PF | - | ±0.025 | |||

| Displacement Power | |||||

| Factor DPF/cos_ | |||||

| Additional uncertainty in% of range | VP-N>250 V | 0.015% | 0.023% | 0.023% | 0.015% |

| 1 In the range of 100 V É 500 V; also known as Udin 2 0 ¡C É 45 ¡C: Intrinsic accuracy x 2, outside of 0 ¡C É 45 ¡C: Intrinsic accuracy x 3 3 Consult operators manual for details Reference conditions: Environmental: 23 ¡C ± 5 ¡C, instrument operating for at least 30 minutes, no external electrical/magnetic field, RH <65 % Input conditions: Cos_/PF=1, Sinusoidal signal f=50 Hz/60 Hz, power supply 120 V/230 V ±10 %. Current and power specifications: Input voltage 1 ph: 120 V/230 V or 3 ph wye/delta: 230 V/400 V Input current: I > 10 % of I range Primary conductor of clamps or Rogowski coil in center position Temperature coefficient: Add 0.1 x specified accuracy for each degree C above 28 ¡C or below 18 ¡C | |||||

| Electrical Specifications | |

| Power Supply | |

| Voltage range | 100 V to 500 V using safety plug input when powering from the measurement circuit |

| 100 V to 240 V MA-C8 and using standard power cord (IEC 60320 C7) | |

| Power consumption | Maximum 50 VA (max. 15 VA when powered using MA-C8 adapter) |

| Efficiency | ³ 68.2% (in accordance with energy efficiency regulations) |

| Maximum no-load consumption | < 0.3 W only when powered using IEC 60320 input |

| Mains power frequency | 50/60 Hz ±15% |

| Battery | Li-ion 3.7 V, 9.25 Wh, customer-replaceable |

| On-battery runtime | Typically 4 hours |

| Charging time | < 6 hours |

| Data Acquisition | |

| Resolution | 16-bit synchronous sampling |

| Sampling frequency | 10.24 kHz at 50/60 Hz, synchronized to mains frequency |

| Input signal frequency | 50/60 Hz (42.5 to 69 Hz) |

| Circuit types | 1-_, 1-_ IT, split phase, 3-_ delta, 3-_ wye, 3-_wye IT, 3-_ wye balanced, 3-_ Aron/Blondel (2-element delta), 3-_ delta open leg, currents only (load studies) |

| Data storage | Internal flash memory (not user replaceable) |

| Memory size | Typical 20 logging sessions of 4 weeks with 1-minute intervals and 500 events |

| Basic Interval | |

| Measured parameters | Voltage, current, aux, frequency, THD V, THD A, power, power factor, fundamental power, DPF, energy |

| Averaging interval | User selectable: 1 sec, 5 sec, 10 sec, 30 sec, 1 min, 5 min, 10 min, 15 min, 30 min |

| Averaging time min/max values | Voltage, Current: Full cycle RMS updated every half cycle (URMS1/2 according to IEC61000-4-30 Aux, Power: 200ms) |

| Demand Interval (Energy Meter Mode) | |

| Measured parameters | Energy (Wh, varh, VAh), PF, maximum demand, cost of energy |

| Interval | User selectable: 5 min, 10 min, 15 min, 20 min, 30 min, off |

| Power Quality Measurements | |

| Measured parameter | Voltage, frequency, unbalance, voltage harmonics, THD V, current, harmonics, THD A, TDD, voltage interharmonics, TID V, current interharmonics, TID A, Flicker, Mains Signaling, under/over deviation |

| Averaging interval | 10 min for all parameters 2 hrs (long term Flicker PLT) 150/180 cycles (3 s) for harmonics (requires software license IEEE519/REPORT) |

| Individual harmonics | 2nd to 50th harmonic Grouping according to IEC 61000-4-7 user configurable depending on application: Sub-grouped (harmonics + interharmonics), grouped or harmonic bins only |

| Interharmonics | 1st to the 50th interharmonic |

| Total harmonic distortion | Calculated on 50 voltage harmonics |

| Events | Voltage: dips, swells, interruptions, current: inrush current 1748: mains signaling, transients (low frequency) |

| Triggered recordings | RMS profile: Full cycle RMS updated every half cycle of voltage and current up to 11 s (URMS1/2 according to IEC 61000-4-30) |

| Waveform of voltage and current up to 200 ms, 10/12 cycles | |

| Mains signaling: 10/12 cycle RMS recording of the configured frequencies up to 120s | |

| Inrush | RMS profile based on 1/2 cycle RMS steady state triggering |

| Flicker | In accordance with IEC 61000-4-15 and IEEE 1453 |

| Mains signaling | Two user defined frequencies up to 3 kHz |

| PQ Health | Summarizes power quality measurements in one table. Detailed data available for each parameter |

| EN 50160 | Compliance with standard |

| Programmable PQ limits | Enables user defined limits for local standards compliance |

| Standards Compliance | |

| Harmonics | IEC 61000-4-7: Class 1 |

| IEEE 519 (short time and very short time harmonics) | |

| Power quality | IEC 61000-4-30 Class A, IEC 62586-1, IEC 62586-2 (PQI-A-PI device) |

| Power | IEEE 1459 |

| Power quality compliance | EN 50160 |

| Safety | General: IEC 61010-1: Pollution Degree 2 |

| Measurement: IEC 61010-2-033: CAT IV 600 V / CAT III 1000 V | |

| Power Supply: Overvoltage Category IV, Pollution Degree 2 | |

| Li-ion Battery: IEC 62133 | |

| Interfaces | |

| USB-A | File transfer via USB flash drive, firmware updates, max. supply current: 120 mA |

| Wi-Fi (free with product registration) | File transfer and remote control via direct connection or Wi-Fi infrastructure |

| Bluetooth | Read auxiliary measurement data from Fluke Connect¨ 3000 series modules (requires supported USB to BLE or Wi-Fi/BLE adapter, check for availability) |

| USB-mini | Data download device to PC |

| Voltage Inputs | |

| Number of inputs | 4 (3 phases referenced to neutral) |

| Maximum input voltage | 1000 Vrms, CF 1.7 |

| Input impedance | 10 M½ |

| Bandwidth | 42.5 Hz to 3.5 kHz |

| Scaling | 1:1 and variable |

| Measurement category | 1000 V CAT III/600 V CAT IV |

| Current Inputs | |

| Number of inputs | 4 (3 phases and neutral), mode selected automatically for attached sensor |

| Input voltage | Clamp input: 500 mVrms/50 mVrms; CF 2.8 |

| Rogowski coil input: 150 mVrms/15 mVrms at 50 Hz, 180 mVrms/18 mVrms at 60 Hz; CF 4 all at nominal probe range | |

| Range | 1 A to 150 A/10 A to 1500 A with thin flexible current probe i17XX-flex1500 IP 24 |

| 3 A to 300 A/30 A to 3000 A with thin flexible current probe i17XX-flex3000 IP 24 | |

| 6 A to 600 A/60 A to 6000 A with thin flexible current probe i17XX-flex6000 IP 36 | |

| 40 mA to 4 A/0.4 A to 40 A with 40 A clamp i40s-EL | |

| Bandwidth | 42.5 Hz - 3.5 kHz |

| Scaling | 1:1 and variable |

| Auxiliary Inputs | |

| Number of inputs | 2 (Analog with auxiliary adapter, or up to 2 BLE devices simultaneously) |

| Input range | 0 to ± 10 V dc, or 0 to ± 1000 V dc (with optional adapter), 1 reading/s |

| Scale factor | Format: mx + b (gain and offset) user configurable |

| Displayed units | User configurable (7 characters, for example, ¡C, psi, or m/s) |

| Wireless Bluetooth connection (check for availability) | |

| Number of inputs | 2 |

| Supported modules | Fluke Connect¨ 3000 series |

| Acquisition | 1 reading/s |

| Environmental Specifications | |

| Operating temperature | -25 ¡C to +50 ¡C (-13 ¡F to 122 ¡F)1 |

| Storage temperature | Without battery: -25 ¡C to +60 ¡C (-13 ¡F to 140 ¡F), with battery: -20 ¡C to +50 ¡C (_4 ¡F to 122 ¡F) |

| Operating humidity | IEC 60721-3-3: 3K6: |

| -25 ¡C to +30 ¡C (-13 ¡F to +86 ¡F): ² 100 % | |

| 40 ¡C (104 ¡F): 55 % | |

| 50 ¡C (122 ¡F): 35 % | |

| Operating altitude | 2000 m (up to 4000 m derate to 1000 V CAT II/600 V CAT III/300 V CAT IV) |

| Storage altitude | 12,000 m |

| Enclosure | IEC 60529: IP50 |

| IEC 60529: IP65 with IP65 rated voltage connector | |

| Vibration | IEC 60721-3-3 / 3M2 |

| Electromagnetic compatibility (EMC) | EN 61326-1: Industrial CISPR 11: Group 1, Class A |

| IEC 61000-6-5 Power station environment | |

| Korea (KCC): Class A Equipment (industrial broadcasting and communication equipment) | |

| USA (FCC): 47 CFR 15 subpart B. This product is considered an exempt device per clause 15.103 | |

| General Specifications | |

| Warranty | Two-years (battery not included) |

| Accessories: one-year | |

| Calibration cycle: two-years | |

| Dimensions | 23.0 cm x 18.0 cm x 5.4 cm (9.1 in x 7.1 in x 2.1 in) |

| Weight | Instrument: 1 kg (2.2 lb) |

| Tamper protection | Accept securing cables (max. _ 6mm) |

| 1Warm up the product to -10 ¡C (+14 ¡F) before you power the unit on | |

| i17XX-FLEX1.5KIP Flexible Current Probe Specifications | |

| Measuring range | 1 to 150 A ac/10 to 1500 A ac |

| Probe cable length | 610 mm (24 in) |

| Probe cable diameter | 7.5 mm (0.3 in) |

| Weight | 170 g (0.38 lb) |

| Minimum bending radius | 38 mm (1.5 in) |

| Nondestructive current | 100 kA (50/60 Hz) |

| Temperature coefficient over operating temperature range | 0.05 % of reading/¡C (0.028 % of reading/¡F) |

| Working voltage | 1000 V CAT III, 600 V CAT IV |

| Output cable length | 2.0 m (6.5 ft) |

| Probe cable material | TPR |

| Weight | 115 g |

| Probe cable material | TPR |

| Coupling material | POM + ABS/PC |

| Output cable | TPR/PVC |

| Operating temperature | -20 ¡C to +70 ¡C (-4 ¡F to 158 ¡F) temperature of conductor under test shall not exceed 80 ¡C (176 ¡F) |

| Temperature, non-operating | -40 ¡C to +80 ¡C (-40

© Lightingandsupplies.com | Sitemap |