DESIGN:

The standards as shown in this section are design to withstand dead loads and theoretical dynamic loads developed by variable wind speeds as charted with an appropriate gust factor under the following conditions: The luminaire(s) and/or mounting bracket(s) center of gravity is assumed to be located at the pole top for all designs. For purposes of design, effective projected area (EPA) is considered to be the product of the actual projected area and the drag coefficient. The listed weights include luminaire(s) and/or mounting bracket(s). The wind velocities are based on 10 mph increments from 80 mph through 100 mph. Standards to be located in areas of known abnormal conditions require special consideration. For example: coastal areas, airports and areas of special winds such as the Chinook type along the eastern slope of the Rocky Mountains.

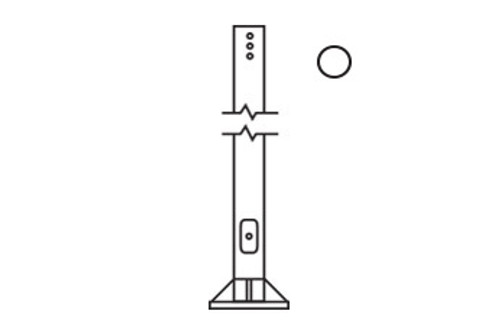

POLE SHAFT:

The pole shall be a one section design fabricated from standard 11 gauge (0.125Ó) or 7 gauge (0.188Ó) aluminum. The shaft will be extruded from all new 6063 series alloy aluminum tubing. Heat treated to produce a T6 Temper. Shafts shall be supplied with a top closure when the shafts are to be drilled for side mounting of luminaires.

HANDHOLE:

The reinforcing handhole rim consists of a nominal 3ÕÕ x 5ÕÕ rectangular shaped tubing material. It is provided with a cover plate, attachment bar and machine screw.

GROUNDING:

Shaft is furnished with ground bolt located inside pole on wall opposite hand hole and a ground bolt will be welded.

ANCHOR BOLTS:

Anchor bolts are hot dipped galvanized in accordance to ASTM-A-153. Anchor bolts are fabricated from hot rolled steel bar with a minimum yield strength of 50,000 psi. Four anchor bolts are provided per pole. Each anchor bolt is furnished with two hex nuts and two flat washers and one lock washer.

ANCHOR BASE PLATE:

The anchor base is cast from A356 alloy aluminum, heat treated to a T6 condition. The base telescopes the pole shaft and is circumferentially welded top and bottom.

POLE BASE COVER:

The pole base cover is spun aluminum construction. The covers are two piece assemblies secured together with two fasteners. (Square base cover is standard and Round cover is optional)

POLE TOP:

All poles come with a removable polymer pole cap installed. Optional to add pole top tenons.

FINISH:

All pole, mounting brackets and platforms shall be polished with fi ne grain aluminum oxide cloths, primer, factory painted and polyester powder coated.

DESIGN:

The standards as shown in this section are design to withstand dead loads and theoretical dynamic loads developed by variable wind speeds as charted with an appropriate gust factor under the following conditions: The luminaire(s) and/or mounting bracket(s) center of gravity is assumed to be located at the pole top for all designs. For purposes of design, effective projected area (EPA) is considered to be the product of the actual projected area and the drag coefficient. The listed weights include luminaire(s) and/or mounting bracket(s). The wind velocities are based on 10 mph increments from 80 mph through 100 mph. Standards to be located in areas of known abnormal conditions require special consideration. For example: coastal areas, airports and areas of special winds such as the Chinook type along the eastern slope of the Rocky Mountains.

POLE SHAFT:

The pole shall be a one section design fabricated from standard 11 gauge (0.125Ó) or 7 gauge (0.188Ó) aluminum. The shaft will be extruded from all new 6063 series alloy aluminum tubing. Heat treated to produce a T6 Temper. Shafts shall be supplied with a top closure when the shafts are to be drilled for side mounting of luminaires.

HANDHOLE:

The reinforcing handhole rim consists of a nominal 3ÕÕ x 5ÕÕ rectangular shaped tubing material. It is provided with a cover plate, attachment bar and machine screw.

GROUNDING:

Shaft is furnished with ground bolt located inside pole on wall opposite hand hole and a ground bolt will be welded.

ANCHOR BOLTS:

Anchor bolts are hot dipped galvanized in accordance to ASTM-A-153. Anchor bolts are fabricated from hot rolled steel bar with a minimum yield strength of 50,000 psi. Four anchor bolts are provided per pole. Each anchor bolt is furnished with two hex nuts and two flat washers and one lock washer.

ANCHOR BASE PLATE:

The anchor base is cast from A356 alloy aluminum, heat treated to a T6 condition. The base telescopes the pole shaft and is circumferentially welded top and bottom.

POLE BASE COVER:

The pole base cover is spun aluminum construction. The covers are two piece assemblies secured together with two fasteners. (Square base cover is standard and Round cover is optional)

POLE TOP:

All poles come with a removable polymer pole cap installed. Optional to add pole top tenons.

FINISH:

All pole, mounting brackets and platforms shall be polished with fi ne grain aluminum oxide cloths, primer, factory painted and polyester powder coated.

Chandeliers

Chandeliers Flush Mount Lighting

Flush Mount Lighting Island Lighting

Island Lighting Pendant Lighting

Pendant Lighting Recessed Lighting

Recessed Lighting Semi-Flush Mount

Semi-Flush Mount Track Lighting

Track Lighting Ceiling Lights Accessories

Ceiling Lights Accessories Wall Sconces

Wall Sconces Table Lamps

Table Lamps Floor Lamps

Floor Lamps Desk Lamps

Desk Lamps Vanity Lighting

Vanity Lighting Picture & Display Lights

Picture & Display Lights Wall Mirrors

Wall Mirrors UFO High Bay

UFO High Bay Round High Bay

Round High Bay Linear High Bay

Linear High Bay Low Bay Lighting

Low Bay Lighting High Bay Accessories

High Bay Accessories Strip Lighting

Strip Lighting Tape Lighting

Tape Lighting Under Cabinet Lighting

Under Cabinet Lighting Linear Fixtures

Linear Fixtures Shop Lighting

Shop Lighting Wraparound Lighting

Wraparound Lighting Rope Lights

Rope Lights Light Bars

Light Bars Linear Retrofit Kits

Linear Retrofit Kits Linear Accessories

Linear Accessories Flat Panel Lighting

Flat Panel Lighting Troffer Lighting

Troffer Lighting Panel & Troffer Accessories

Panel & Troffer Accessories Emergency Lighting

Emergency Lighting Exit Signs

Exit Signs Grow Lights

Grow Lights Vapor Tight Lighting

Vapor Tight Lighting Hazardous Location

Hazardous Location UV & Germicidal Lights

UV & Germicidal Lights Cooler & Refrigeration

Cooler & Refrigeration10-30wsideviewresized__27828.1721148389__94320.1749913681.jpg?c=2) Garage Lighting

Garage Lighting Work Lights

Work Lights Stairway Lighting

Stairway Lighting Fans with Lights

Fans with Lights Fandeliers

Fandeliers Hugger Fans

Hugger Fans Fan Accessories

Fan Accessories Wall Packs

Wall Packs Barn Lights

Barn Lights Bulkhead Lights

Bulkhead Lights Wall Pack Accessories

Wall Pack Accessories Flood Lighting

Flood Lighting Spotlights

Spotlights Security Lighting

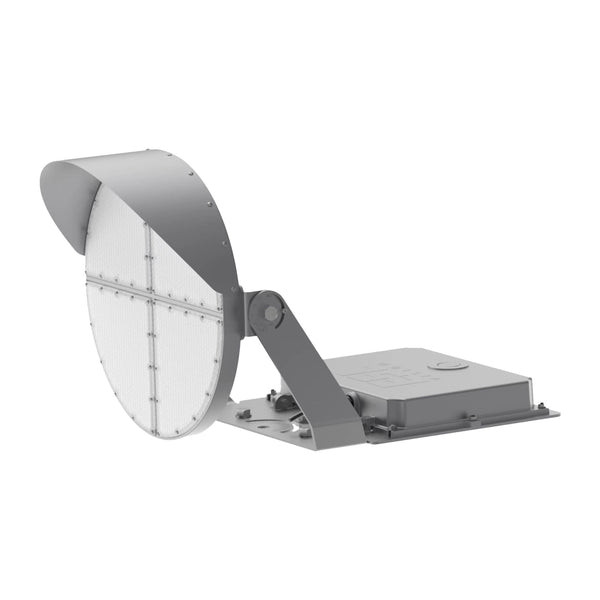

Security Lighting Stadium & Sports Lighting

Stadium & Sports Lighting Flood Light Accessories

Flood Light Accessories Area Lights

Area Lights Post Top Lighting

Post Top Lighting Area Light Accessories

Area Light Accessories Path Lights

Path Lights Bollard Lights

Bollard Lights Deck & Step Lights

Deck & Step Lights In-Ground & Well Lights

In-Ground & Well Lights Spot Lights

Spot Lights Hardscape Lights

Hardscape LightsPOLETOPMOUNTRESIZED__72860.1721147852__60616.1749923956.jpg?c=2) Solar Lights

Solar Lights Landscape Accessories

Landscape Accessories Street Lights

Street Lights Pole Lights

Pole Lights Roadway Lighting

Roadway Lighting Round Canopy

Round Canopy Square Canopy

Square Canopy Canopy Accessories

Canopy Accessories Outdoor Wall Lanterns

Outdoor Wall Lanterns Outdoor Wall Sconces

Outdoor Wall Sconces Hanging Lanterns

Hanging Lanterns Porch Lighting

Porch Lighting Outdoor Pendant Lighting

Outdoor Pendant Lighting Cylinder Lighting

Cylinder Lighting String & Festoon Lights

String & Festoon Lights Dusk to Dawn Lighting

Dusk to Dawn Lighting Marine Lighting

Marine Lighting Pool & Pond Lighting

Pool & Pond Lighting Sign Lighting

Sign Lighting A-Shape (A19 / A21)

A-Shape (A19 / A21) PAR LED Bulbs

PAR LED Bulbs BR LED Bulbs

BR LED Bulbs MR LED Bulbs

MR LED Bulbs LED Tube Lights

LED Tube Lights Candelabra LED Bulbs

Candelabra LED Bulbs Globe LED Bulbs

Globe LED Bulbs Decorative LED Bulbs

Decorative LED Bulbs R LED Bulbs

R LED Bulbs LED Corn Bulbs

LED Corn Bulbs Smart LED Bulbs

Smart LED Bulbs LED Retrofit Kits

LED Retrofit Kits Linear Fluorescent Tubes

Linear Fluorescent Tubes Compact Fluorescent (CFL)

Compact Fluorescent (CFL) Plug-In CFL

Plug-In CFL Circline Bulbs

Circline Bulbs Halogen Bulbs

Halogen Bulbs Standard Incandescent

Standard Incandescent Vintage & Edison Bulbs

Vintage & Edison Bulbs Metal Halide

Metal Halide High Pressure Sodium

High Pressure Sodium Low Pressure Sodium

Low Pressure Sodium Mercury Vapor

Mercury Vapor Appliance Bulbs

Appliance Bulbs Colored Bulbs

Colored Bulbs UV Bulbs

UV Bulbs Blacklight Bulbs

Blacklight Bulbs Grow Bulbs

Grow Bulbs Sign Bulbs

Sign Bulbs Projector Bulbs

Projector Bulbs Indicator & Miniature

Indicator & Miniature Capacitors

Capacitors Connectors & Adapters

Connectors & Adapters Fuses & Breakers

Fuses & Breakers Junction Boxes

Junction Boxes Outlets & Receptacles

Outlets & Receptacles Sockets & Lampholders

Sockets & Lampholders Wall Plates

Wall Plates Wire Connectors

Wire Connectors Dimmers

Dimmers Motion Sensors

Motion Sensors Occupancy Sensors

Occupancy Sensors Photocells

Photocells Smart Controls

Smart Controls Switches

Switches Timers

Timers Batteries

Batteries Electrical Tapes

Electrical Tapes Flashlights

Flashlights Multimeters & Testers

Multimeters & Testers Nut Drivers

Nut Drivers Pliers

Pliers Safety Equipment

Safety Equipment Screwdrivers

Screwdrivers Tape & Adhesives

Tape & Adhesives Tool Kits

Tool Kits Wire Strippers & Cutters

Wire Strippers & Cutters Weatherproof Covers

Weatherproof Covers Electronic Transformers

Electronic Transformers Low Voltage Transformers

Low Voltage Transformers Magnetic Transformers

Magnetic Transformers Cable Management

Cable Management Electrical Wire

Electrical Wire Extension Cords

Extension Cords Brackets & Arms

Brackets & Arms Light Poles

Light Poles Mounting Accessories

Mounting Accessories Pole Mounts & Tenons

Pole Mounts & Tenons Slipfitters

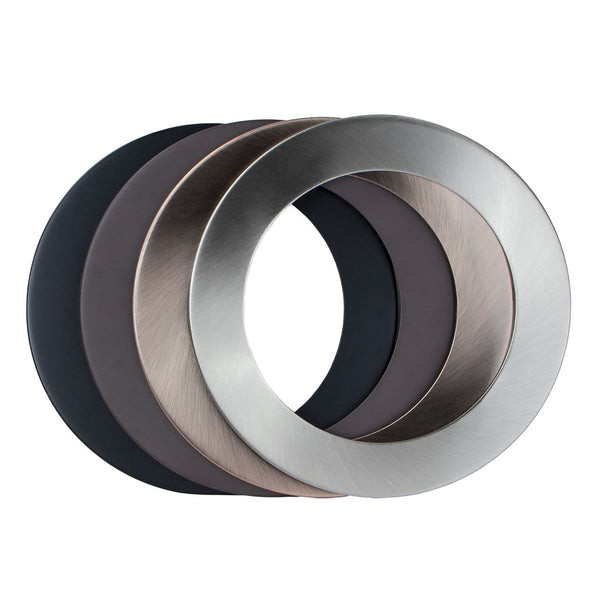

Slipfitters Trim Rings & Reflectors

Trim Rings & Reflectors Electronic Ballasts

Electronic Ballasts Emergency Ballasts

Emergency Ballasts Fluorescent Ballasts

Fluorescent Ballasts HID Ballasts

HID Ballasts LED Drivers

LED Drivers Magnetic Ballasts

Magnetic Ballasts Backup Batteries

Backup Batteries C7 Lights

C7 Lights C9 Lights

C9 Lights Mini Lights

Mini Lights Christmas Trees

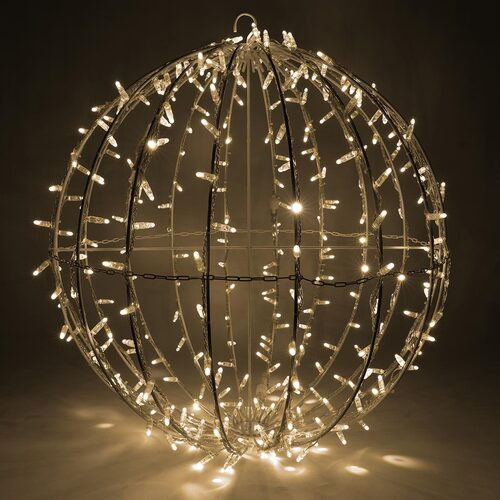

Christmas Trees Outdoor Decorations

Outdoor Decorations Wreaths & Garlands

Wreaths & Garlands Patio String Lights

Patio String Lights Wedding & Event Lights

Wedding & Event Lights Battery Operated Lights

Battery Operated Lights Novelty Lights

Novelty Lights Icicle Lights

Icicle Lights Curtain Lights

Curtain Lights Net Lights

Net Lights Rope Lights

Rope Lights Commercial Christmas Lights

Commercial Christmas Lights Christmas Light Accessories

Christmas Light Accessories